In the early 20th Century the job of process improvement was limited to a handful of industrial engineering specialists. They studied the work, organized the jobs, and told everyone else how it should be done. Today, however, we want as many people as possible – especially our front line leaders – to fully participate in process improvement; not only to help improve the work, but to develop as leaders. With these skills they can turn their challenges into meaningful action.

In this course we will focus on the first critical steps of this process, “Grasp the Current Condition.” This is a hands-on practicum over six sessions.

In each session we will introduce a new topic, answer questions, and assign a task or exercise that deepens your understanding of that step or presents an opportunity to practice it in your own workplace. The objective is that you can not only apply these steps, you can also help others learn to apply the steps themselves.

Over six sessions, we will explore together:

- Extracting performance metrics from a challenge

- Determining the required operating cadence

- Capturing a process in a block diagram

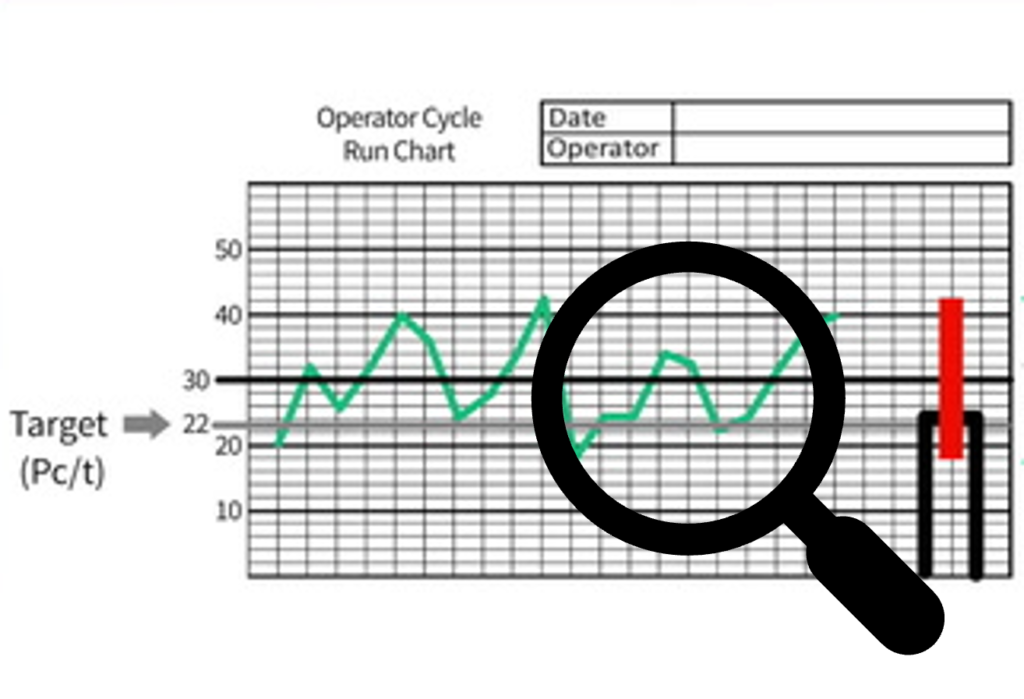

- Timing exit cycles and documenting variation – run charts and load charts

- Determining machine constraints and calculating people required

- What does this all mean? Interpreting your process analysis to set a next target condition.

Each week you will have assignments to practice and apply what we are learning together to different processes. You can count on a hour or more outside the online time together.

Facilitator bio

Mark Rosenthal is a results driven lean director and manager with over twenty years’ experience implementing lean manufacturing and continuous improvement across diverse industries including aerospace, consumer products, health imaging, and heavy equipment. He has a deep understanding of the Toyota Production System with proven ability see any organization’s potential, cut to the core issues, gain “buy-in” and get things moving by engaging the entire team to develop solutions to impact the bottom line. He is also the author of “The Lean Thinker,” a blog where he shares his insights and experiences from the shop floor, contributing valuable perspectives to the lean community. As a sought-after speaker, Mark frequently presents at lean conferences, sharing his expertise on topics like the integration of Toyota Kata into organizational practices.

Logistics

📅 Date: May 6, 8, 13, 15*, 20, 22

⏰ Time: 9-10am (Pacific) *0-10:30 on May 15th

📌 Location: Virtual

💰Cost: $325 members ($525 nonmembers)

To register, email jennifer@nwhpec.com with participant name(s), email(s), and job title(s).

Invoices will be sent to your company representative around April 24th. No refunds are available after April 24th. Your best option is to transfer your seat to someone else in your organization.