Creating a Culture of Continuous Improvement with Mark Rosenthal

March 11 @11am (PT)

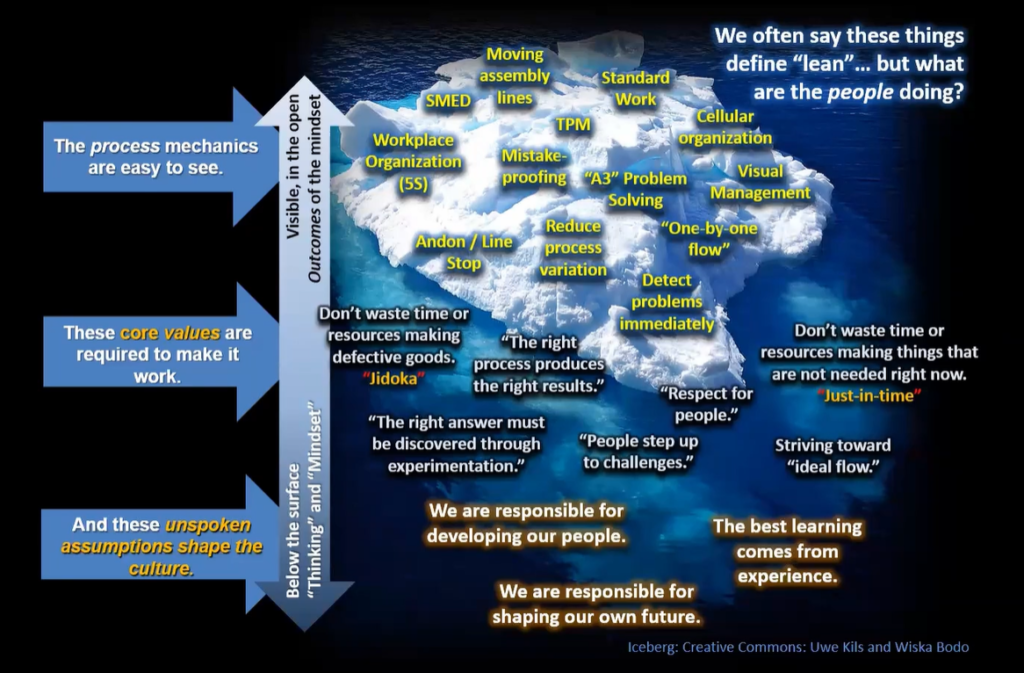

The phrase “creating a lean culture” is often used in organizations striving for daily continuous improvement—but what does that actually mean? What would we see in an organization that has truly embraced lean?

In this webinar, Mark Rosenthal will challenge us to move beyond vague aspirations with regards to lean and focus on the observable behaviors and interactions that define a lean culture. We often talk about the outcomes of lean, but culture isn’t a static thing—it emerges from the daily habits and patterns of how people work together. People learn what they practice – what are you practicing?

For improvement to be truly continuous, everyone needs to be involved. But in many organizations process improvement is limited to a handful of specialists. In this session we will discuss:

- How benchmark organizations work to solve problems in ways that develop people’s problem solving skills.

- What is different in the day-to-day patterns and habits within those organizations.

- How Toyota’s famed andon (line stop) is a driver for process improvement.

- One (developing) example of how a company is working to incorporate process improvement into their daily management system.

- The importance of building process improvement skills at the team-leader and supervisor level.

Come armed with your questions and ready to challenge your paradigms (or have them challenged!).

More about our speaker, Mark Rosenthal:

Mark is a results driven lean director and manager with over twenty years’ experience implementing lean manufacturing and continuous improvement across diverse industries including aerospace, consumer products, health imaging, and heavy equipment. He has a deep understanding of the Toyota Production System with proven ability see any organization’s potential, cut to the core issues, gain “buy-in” and get things moving by engaging the entire team to develop solutions to impact the bottom line. He is also the author of “The Lean Thinker,” a blog where he shares his insights and experiences from the shop floor, contributing valuable perspectives to the lean community. As a sought-after speaker, Mark frequently presents at lean conferences, sharing his expertise on topics like the integration of Toyota Kata into organizational practices.

Mark will be facilitating our “Process Analysis Deep Dive” workshop in April, so this is a great chance to get to know him.

Logistics:

📅 Date: Tuesday, March 11, 2025

⏰ Time: 11-11:45am (Pacific)

📌 Venue: Online via Zoom

🔗Registration: click the button below