LEAN 101: 6-WEEK SERIES – April 28th – June 2nd (Full)

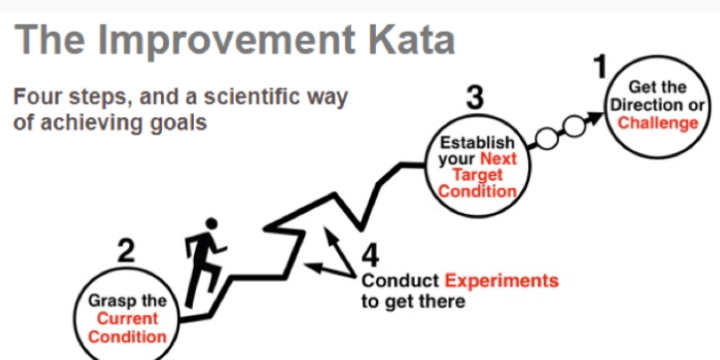

Lean 101(a virtual learning experience) FULL - the next class will start in September Join us on a journey to discover the basic elements of lean principles and see the impact they make when you put them into practice. This course consists of six, one-hour classes focused on the foundational elements of lean. During this course, you will learn more about the history/background of lean, why these principles are important to creating a culture of excellence, standard work, 8 wastes, 5S, PDCA, and visual management. Each week will include instruction, discussion, and simulations followed by small project assignments between each class to help you practice the concepts in your own environment.Lean 101 is a beginning-level course that teaches participants the basic concepts of Lean Thinking. It is suitable for participants…